At present, the large-scale breeding development in China tends to be stable, but the discharge of a huge amount of livestock and manure with no or simple treatment has become a major cause of the deterioration of the agricultural ecological environment, as well as an obstacle to the sustainable development of the breeding industry. Therefore, harmless treatment and resource utilization of livestock manure for the prevention and elimination of pollution caused by livestock manure from the breeding farms is of very important significance to the protection of ecological environment and promotion of sustainable development of agriculture.

Farming requires organic fertilizer, yet manure generated from breeding fails to be effectively utilized

As an ancient saying goes, “corps must be fertilized to grow well”, and “more pigs bring more fertilizer, which means a higher yield of grains”. The fertilizer mentioned here refers to organic fertilizer and farmyard manure. It can be seen that manure has always been an important fertilizer for farming in China since ancient times. However, at present, various types of organic fertilizer resources in China can be converted into more than 74 million tons of nutrients, but the actual utilization rate is less than 40%. As for the reasons, firstly, organic fertilizer has the problems such as low nutrient content, slow fertilizer efficiency, large volume and inconvenient use; secondly, the large amount of demand for livestock manure in the farming industry is seasonal, while the manure generated from the large-scale breeding farms is too intensive without much difference among different seasons; and most importantly, the huge amount of livestock manure generated from large-scale breeding are not used effectively.

What are the hazards of poor treatment of manure generated from large-scale breeding?

Since the huge amount of livestock manure is not effectively utilized, the biggest environmental problem facing large-scale breeding farms is manure treatment. It takes a few months for manure piled up to naturally become thoroughly decomposed. During this period, mosquitoes and flies are all over the place and bad smell befouls the atmosphere. Being exposed to the sun and rain, the livestock manure pollutes the environment and loses nutrients. Many farmers lack patience and often put it on the farmland after only a few days. As a result, crops burn their seedlings and roots, and the seeds are not germinated and die. The imperfect treatment mode causes local pollution, affects ecological imbalance and leads to frequent production suspense and bans on breeding of the breeding farms. As a result, the economy cannot be developed and the environment is destroyed, leading to the situation of losses out-weighting gains.

It is necessary to carry out harmless treatment and resource utilization of livestock manure.

It affects effective supply of livestock products,

cost saving and efficiency improvement of the livestock breeding industry,

the sustainable development of the breeding industry,

and the improvement of the production and living environment for rural residents.

It is a major livelihood project.

How to recycle livestock manure?

The resource utilization of livestock manure refers to the rational use of livestock manure in the treatment process by means such as producing biogas, composting, waterlogged compost, biogas manure, rich water, padding and base materials through anaerobic digestion.

The main technologies for resource utilization of manure include sewage treatment and solid waste treatment:

1. Sewage

Liquid or all manure is generally treated by anaerobic fermentation. It is treated with the continuous stirred tank reactor (CSTR), up-flow anaerobic sludge bed (UASB) and other equipment, supported by the regulating reservoir, the anaerobic fermentation tank, the solid-liquid separator, the gas storage facility, the biogas residue and slurry storage pool and other facilities. The Technical Specifications for Biogas Engineering (NY/T 1220) is implemented for relevant construction requirements. If biogas is used for electricity generation or bio-natural gas is purified, the biogas power generation and purification facilities and other equipment will be provided as needed.

2. Solid manure

Solid manure is generally made into organic fertilizer for utilization with the method of aerobic fermentation.

At present, the method of producing organic fertilizer by aerobic composting is widely used, but there are generally the problems of shortage of organic fertilizer sales market and difficulty in gaining returns on investment in equipment and fixed assets for organic fertilizer production. The high-temperature aerobic fermentation composting method is an effective method for treating various organic wastes, as well as a biological method integrating treatment and recycling of resources.

Through the purposeful degradation, the biochemical treatment technology that converts organic matters into humus can achieve harmless and resource utilization of raw materials. Such method of manure treatment has the advantages of less bad smell, drier final products, and easy packaging and broadcasting, and it is beneficial to the growth of crops. For compost, waterlogged compost, biogas manure, rich water and others which are returned to the field for utilization, the matching farmland area should be determined reasonably according to the technical guide for the calculation of land bearing capacity of manure generated from livestock breeding, and the Technical Specification for Livestock Manure Returning to the Field (GB/T 25246) and the Technical Specification for Biogas Manure Application (NY/T 2065) should be implemented.

Yingherui’s mode of recycling livestock breeding wastes

Yingchuang Hemei, a subsidiary of Yingherui, adopts the principle of being “guided by the government, dominated by enterprise and operated in the market” and integrates financial capital and industrial capital to link upstream breeding enterprises and downstream planting enterprises. With the bonds of organic fertilizer and biogas manure, it integrates breeding and farming and invests in the construction of a regional comprehensive agricultural organic waste treatment center and an ecological agricultural planting demonstration park which focus on fully quantitative professional manure treatment, sick and dead livestock disposal, comprehensive biogas utilization and organic fertilizer production and sales.

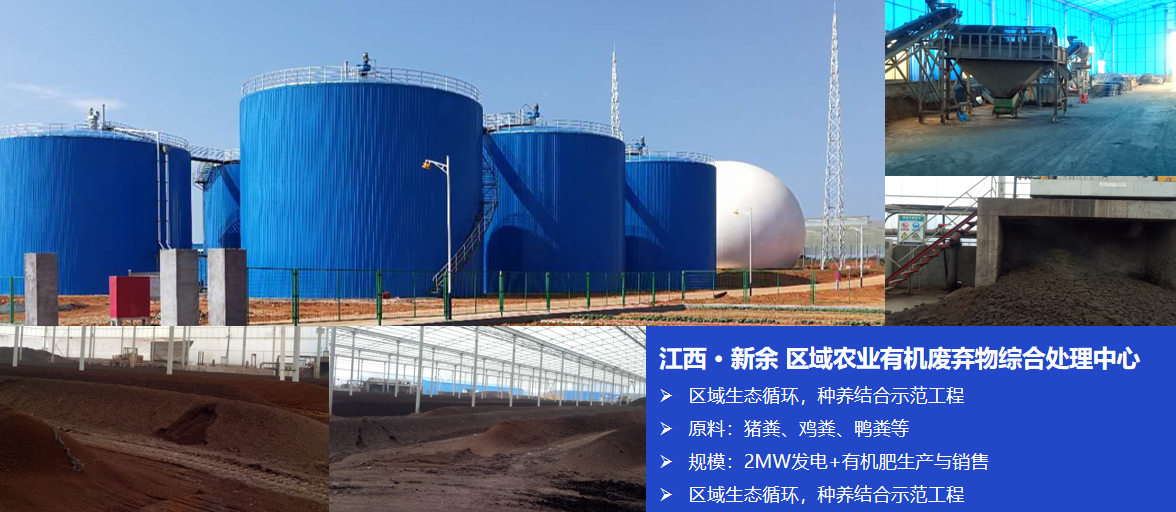

Regional comprehensive agricultural organic waste treatment center in Xinyu, Jiangxi

A demonstration project of regional ecological cycle and integration of planting and breeding

Raw materials: pig manure, chicken manure, duck manure, etc.

Scale: 2MW power generation + organic fertilizer production and sales

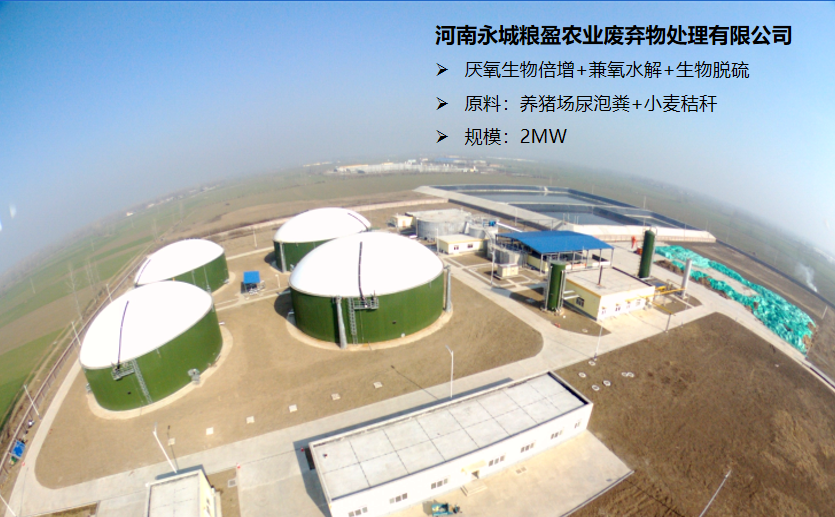

Henan Yongcheng Liangying Agricultural Waste Treatment Co., Ltd.

Anaerobic biological multiplication + facultative anaerobic hydrolysis + biological desulfurization

Raw materials: manure cleaned by water submerging at the pig farm + wheat straws

Scale: 2MW

Case description: Henan Yongcheng Liangying Agricultural Waste Treatment Co., Ltd. constructed with the investment of Yingherui

Yongcheng Liangying uses manure from the pig farms, wheat straws and corn straws as the basic materials, and targets at biogas power generation and organic fertilizer production. It adopts the ecological utilization mode combining grid-connected biogas power generation and utilization of biogas slurry by returning it to the field. The process can be summarized as fermenting livestock manure through anaerobic biological multiplication and treating straws with the facultative hydrolysis technology to produce biogas, biogas residue and biogas slurry.

Biogas is used as energy to supply gas for daily life in the pig farms, heating boiler for the fermentation tank and grid-connected biogas power generation. Then, through the equipment of the liquid organic and inorganic compound fertilizer production line owned by the company, biogas slurry can go through acidification, flocculation, filtration, complexation and compounding and other technical processes to produce fertilizers such as water flush fertilizer, foliar fertilizer and nutrient solution for soilless culture, which can not only promote crop growth and significantly reduce the use of chemical fertilizers, but also improve soil to achieve sustainable development of ecological recycling.

This agro-ecological project aiming at protecting the agro-ecological environment achieves all-around and multi-level development and utilization of biologicalgermplasm resources and achieves an effective combination of the planting and breeding industries. It is the best way to utilize the manure resources.

All regional comprehensive agricultural organic waste treatment centers invested by Yingherui adopt the factory management mode and build anaerobic fermentation equipment that meets the agricultural manure treatment capacity produced by breeding and agricultural planting according to the specifications. These centers meet the upper limit of production and test nutrients of the biogas slurry every quarter. By taking into consideration the types of planted crops and contents of soil nutrients and biogas slurry nutrients, the centers give fertilization schemes, strictly control the amount of biogas slurry used, establish on-site fertilization management systems, require the implementation of on-site management of fertilization sites and inspect the pipelines along the way, so as to achieve safe and scientific use of biogas fertilizer and realize resource utilization of biogas slurry.

Data reference: Agriculture Today