Quick installation

Modular design and component transportation, professional installation tools, reverse installation, less aloft work, strong temperature adaptability, and much shorter construction period.

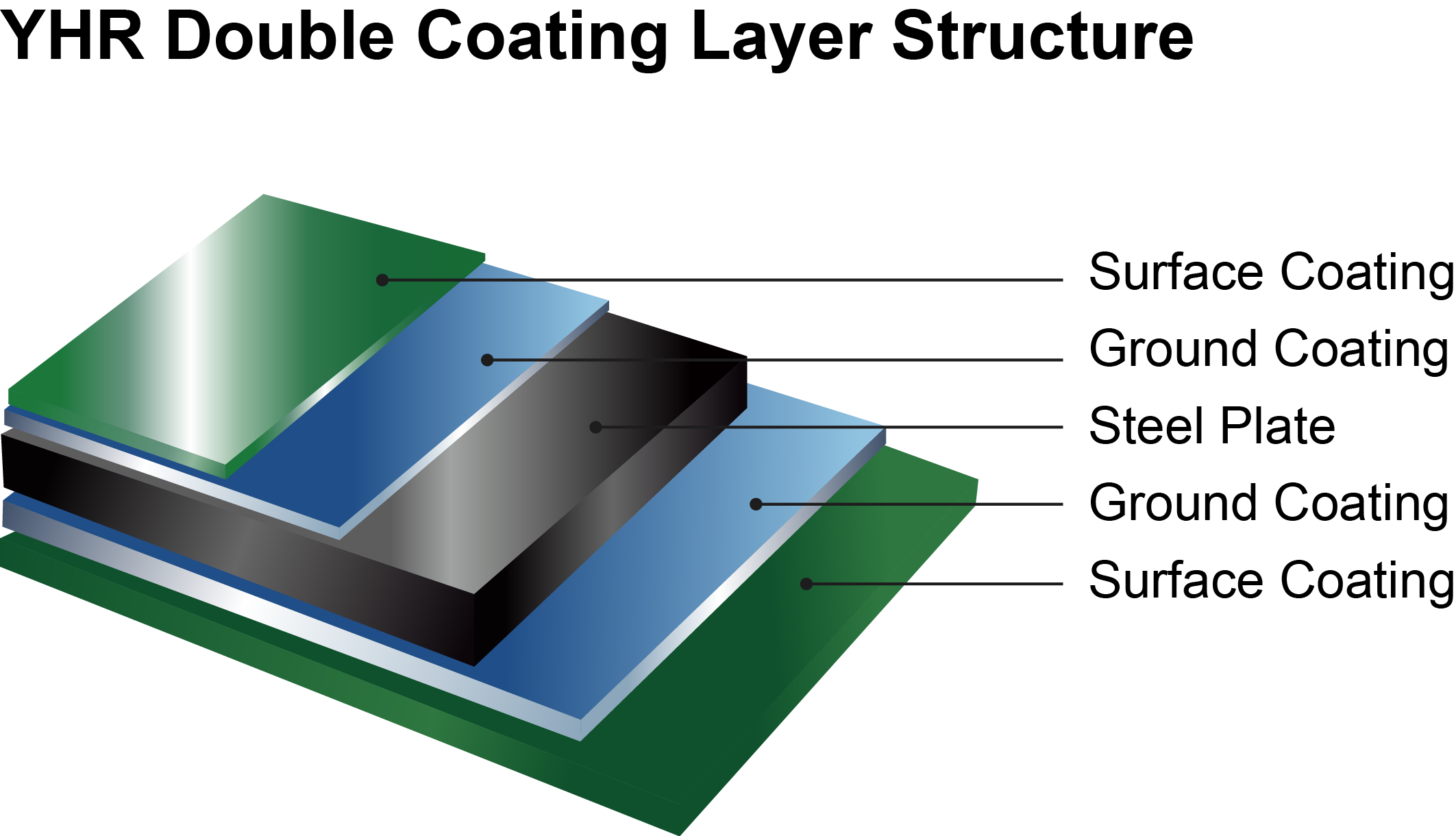

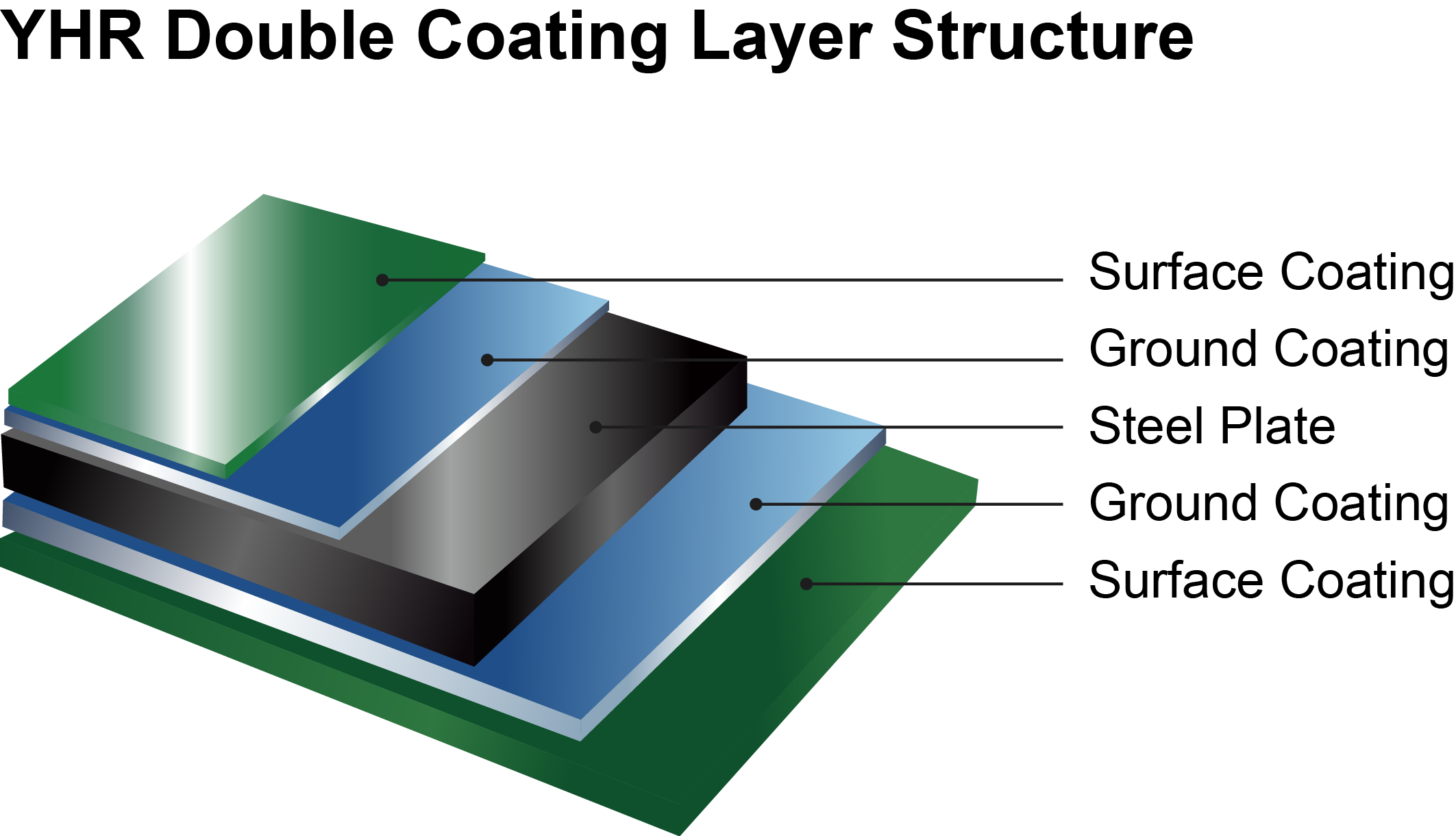

Good anti-corrosion performance

The highly inert glaze layer has excellent anti-corrosion performance, strong adaptability to inorganic and organic environments, high strength and impact resistance, and is not easy to fall off, with a service life of more than 30 years.

High standard

Factory production, high degree of standardization, and controllable quality

Maintenance free

No later maintenance is required after the tank is completed

Recoverable

The tank can be moved, expanded and recycled.